The metallic casting business is constantly evolving, driven with the desire for larger precision, improved excellent, and reduced defects. Within this landscape, the stress casting device plays a vital purpose. nevertheless, for probably the most demanding applications, a specialized variety of casting machine is necessary: the vacuum strain casting equipment. this informative article explores the one of a kind benefits of these devices, specializing in how they greatly enhance the accuracy and top quality of metal casting, specifically for treasured metals like gold and platinum.

Table of contents:

some great benefits of working with Vacuum strain Casting equipment for top-Quality effects

How Vacuum stress Casting improves the precision of Gold, Platinum, and also other Metals

Why Vacuum tension Casting is important for higher-Precision Industries

the benefits of employing Vacuum stress Casting devices for prime-high quality effects

Vacuum force casting equipment give a major breakthrough compared to traditional casting approaches. The Main gain lies from the elimination of air pockets and gasoline porosity inside the casting. By performing the casting method underneath a vacuum, the molten metal is permitted to flow more freely and totally fill the mildew cavity. This ends in denser, more robust castings with much less inside defects. Also, the appliance of tension in the course of the solidification section helps to further consolidate the metallic, reducing shrinkage and increasing the general quality. This will make vacuum tension casting perfect for producing intricate and complex designs exactly where even the smallest imperfections can compromise the features or get more info aesthetic attractiveness of the ultimate merchandise.

How Vacuum force Casting improves the Accuracy of Gold, Platinum, along with other Metals

The higher value and one of a kind Houses of valuable metals like gold and platinum necessitate Extraordinary casting precision. Vacuum gold casting machine engineering is specially built to satisfy these demanding needs. The vacuum surroundings not simply stops oxidation of your molten steel but additionally ensures a thoroughly clean and consistent casting approach. This is especially crucial for gold, which can certainly tarnish or build surface defects if subjected to air through casting. Also, the controlled strain utilized in the course of solidification encourages uniform grain composition and minimizes the chance of cracking or distortion. This ends in castings that happen to be dimensionally accurate, have outstanding surface area finish, and retain the specified mechanical Attributes.

Why Vacuum stress Casting is Essential for large-Precision Industries

High-precision industries, including aerospace, professional medical device manufacturing, and large-finish jewellery manufacturing, trust in vacuum pressure casting to obtain the stringent high quality requirements demanded for their apps. the chance to generate castings with limited tolerances, minimal defects, and reliable material Houses is paramount in these sectors. as an example, in the aerospace business, vacuum pressure Solid components are Utilized in critical engine pieces where by trustworthiness and efficiency are non-negotiable. likewise, in professional medical machine producing, vacuum strain casting makes certain the biocompatibility and structural integrity of implants. The benefits prolong to jewelry creating as well, where intricate styles and flawless finishes are important for building superior-price parts. Ultimately, vacuum force casting presents the necessary Regulate and precision to satisfy the demanding needs of such industries. As evidenced by goods such as TAKJ-VC-W accessible at https://taeantech.com/products/takj-vc-w, these machines are especially designed to cater for the precision necessary by vacuum stress casting procedures.

In summary, vacuum tension casting machines are indispensable tools for attaining significant precision and top-quality high quality in steel casting. The mix of vacuum environment and managed force eradicates prevalent casting defects, enhances content Attributes, and assures dimensional precision. For industries demanding the best levels of general performance and dependability, buying vacuum strain casting technology is not simply a selection but a necessity. look at the certain requirements of your application and examine the various vacuum tension casting alternatives available to unlock new possibilities in steel casting and elevate the standard of your closing merchandise.

Anna Chlumsky Then & Now!

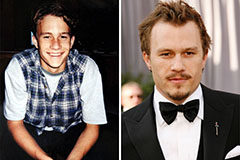

Anna Chlumsky Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now!